Ultrathin Fuel Cells: Converting Glucose into Electric Energy

The abundance of monosaccharide glucose (C6H12O6) is the main component of human blood. As it is also the most important carbohydrate fuel of the body, its increase in the blood can cause severe issues to the human body. Glucose usually enters our body in the form of galactose and fructose, lactose, and sucrose or starch. It undergoes several biochemical reactions and is broken down into energy that is released in the form of ATP. Now the Engineers from MIT and the Technical University of Munich have built a new technique to convert glucose directly into electric energy.

Key Components of Ultrathin Fuel Cell

Ultrathin fuel cells (UFC) are easily distinguishable from other glucose fuel cells. UFC measures just 400 nanometers thick; in other words, about 1/100 the diameter of a human hair. The sugary power source generates about 43 microwatts per square centimeter of electricity, achieving the highest power density of any glucose fuel cell to date under room temperature. UFC can tolerate temperatures up to 600 °C. It is often used in medical implantation, as the fuel cell could remain stable through the high-temperature sterilization process required for all implantable devices.

To reduce the Ohmic loss in the cell voltage of fuel cells, the electrolyte should be made as thin as possible, particularly when alkaline polymer electrolytes (APEs) are occupied, where both the mobility and the concentration of OH− are relatively low. A practical strategy for fabricating thin APE membranes is to impregnate APE ionomers into an ultrathin, rigid framework (such as a porous PTFE film) so that high ion conduction is achieved by the APE with a high ion-exchange capacity (IEC) while mechanical stability is provided by the vigorous host. Previous experimentation realized a prototype of an APE fuel cell (APEFC) using this kind of composite membrane, but it was later found that the APE component, quaternary ammonium polysulfide (QAPS), will leak out under the fuel cell's operating conditions because of the poor interaction between the QAPS guest and the PTFE host. To address this problem, researchers demonstrate a new approach for making ultrathin composite membranes of APEs. The APE ionomer (TQAPS) is impregnated into a porous PTFE film, followed by a self-crosslinking process to form a semi-interpenetrating network. The resulting ultra-thin composite membrane (xQAPS@PTFE, 25 μm thick) is highly tolerant to leaching in 80 °C water and possesses low area resistance (0.09 Ω cm2), a low swelling degree, and high mechanical strength (31 MPa). Using such an xQAPS@PTFE membrane, the H2–O2 APEFC exhibits a peak power density of 550 mW cm2 at 60 °C under 0.1 MPa of back pressure.

The brain of the new device is made up of ceramic material that holds its electrochemical properties even at high temperatures and miniature scales. The researchers postulated that the new design could be made into ultrathin films or coatings wrapped around implants to passively power electronics, using the body’s ample glucose supply.

“In the doctor’s office, I was a very bored electrochemist, thinking about what you could do with sugar and electrochemistry. Then I realized it would be good to have a glucose-powered solid state device.” says Prof. Jennifer Rupp. She is a Visiting Associate Professor in the Department of Materials Science and Engineering.

Philipp Simon, Ph.D., MIT’s Department of Materials Science and Engineering (DMSE), says, “Glucose is everywhere in the body, and the idea is to harvest this readily available energy and use it to power implantable devices. In our work we show a new glucose fuel cell electrochemistry.”

The cell comprises three layers, an anode, an electrolyte, and a cathode. The anode reacts with the sugar in bodily fluids, releasing a pair of protons and a pair of electrons during the process. The electrolyte then takes the electrons to an external circuit, where it’s used to power an electronic device. Meanwhile, the protons go through the cathode, where it reacts with oxygen to form a harmless water by-product.

High-Temperature Resistant

The researchers designed a glucose fuel cell with an electrolyte made from ceria, a ceramic material that possesses high ion conductivity, is mechanically robust, and is widely used as an electrolyte in hydrogen fuel cells. It has also been shown to be biocompatible. Ceria is actively studied in the cancer research community. It’s also similar to zirconia, which is used in tooth implants and is biocompatible and safe.

The team is not the first to consider a glucose fuel cell. This was first introduced in the 1960s and showed potential for converting glucose’s chemical energy into electrical energy. But glucose fuel cells at the time were based on soft polymers. They were quickly eclipsed by lithium-iodide batteries, which would become the standard power source for medical implants, most notably the cardiac pacemaker.

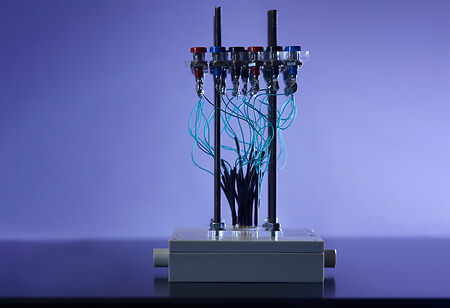

The team merged the electrolyte with an anode and cathode made of platinum, a stable material that readily reacts with glucose. They fabricated 150 individual glucose fuel cells on a chip, each about 400 nanometers thin and about 300 micrometers wide (about the width of 30 human hairs). They patterned the cells onto silicon wafers, showing that the devices can be paired with a common semiconductor material. They then measured the current produced by each cell as they flowed a glucose solution over each wafer in a custom-fabricated test station. They then saw cells producing a high voltage of 80 millivolts. This makes the new GFC unique from the existing ones.

Surprisingly researchers were able to draw current and power to use in the implantation. It is the first time that proton conduction in electro ceramic materials could be used for glucose-to-power conversion, defining a new type of electrochemistry. It extends the material use-cases from hydrogen fuel cells to new, exciting glucose-conversion modes.

“The researchers have opened a new route to miniature power sources for implanted sensors and maybe other functions. The ceramics used are nontoxic, cheap, and not least inert both to the conditions in the body and to conditions of sterilization prior to implantation. The concept and demonstration so far are promising indeed,” says Truls Norby, a professor of chemistry at the University of Oslo in Norway.